EMS (Electronic manufacturing services) are services offered by companies that build, test, design, deliver and offer after-sale assistance for electronic parts and assemblies. In this article, we are going to discuss the services offered by an EMS company, and what an EMS company does.

What you should expect from an electronic manufacturing services

The services of an EMS company can vary depending on the level of involvement and the size of your product. However, there are general services that you should expect from an EMS company. They include;

PCB assembly: This is the first step of the electronic manufacturing process. According to PCI (https://www.pciltd.com/), the electronic component manufacturers send their components to an EMS provider, who will make the circuit boards out of them, design a printed circuit board, or create sheet metal parts.

Cable assembly: This is a process where the wires are used to connect the electronic components.

Electromechanical assembly: This service is offered when electronic components are combined with electromechanical components such as on-off switches and sensors.

Contract design: This involves designing the circuit boards and printed circuit boards. The design is drafted and sent to the customer for approval before the job is started.

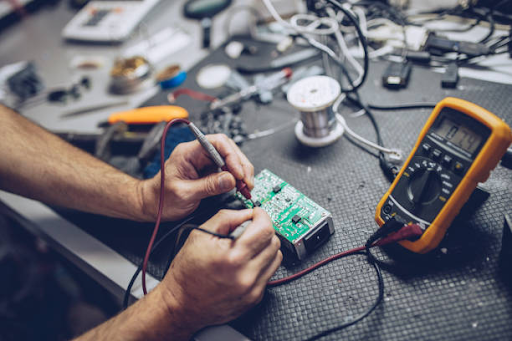

Testing: What this entails is testing the circuits to ensure they are working and that there are no failures.

Prototyping: This is where an electronic component manufacturer sends their product to an EMS company and the company creates a physical form of the product. What follows is the production of the physical product that is done by the EMS provider.

Aftermarket services: These include providing technical support and maintenance of the product.

Laser ID Marking on PCBs: Laser marking is a new technology that enables the automated and numeric identification of electronic products. Here, an EMS company will make all the components and assemble them into circuit boards. The circuit boards are then laser-marked with a serial number or identifying information.

Conformal coating: This is a process in which the circuit board is placed on a circuit board and then coated to protect it from corrosion or damage.

Repair and revision upgrading: This is a process where a product that has already been sold is brought back to the EMS provider who will fix any errors in it.

Burn-in and thermal cycling: This is a process where the electronic products are exposed to high temperatures to check for burnout.

Cleaning: This entails using solvents and cleaning chemicals to clean any external dirt. This is vital, especially for products that have sensitive circuits.

Electronic Design and Manufacturing process

In the EMS process, there are four main steps; design and order, pre-production prototype, production, and post-production support.

Design and order: This is where an electronic manufacturer will send their product design to an EMS provider. The provider will then create a physical form of the product and test it to ensure it can work properly.

Pre-production prototype: Before production begins, the provider prototypes the product to test it. This process is called Prototyping.

Production: At this stage, the provider will start production of the product.

Post-production support: After the production stage, the provider will do any sort of post-production support. This entails selling the product, repairing it, and providing any sort of after-sales support.

There are also other processes that these companies undertake such as burn-in and thermal cycling, which enable them to be more efficient.

EMS companies can create highly complex electronic designs and offer clients a variety of production methods. They effectively manage the production process and ensure that the products are designed as per the customer’s requirements.

… [Trackback]

[…] Find More here to that Topic: news969.com/what-does-an-electronic-design-and-manufacturing-services-company-do/ […]

… [Trackback]

[…] Find More on on that Topic: news969.com/what-does-an-electronic-design-and-manufacturing-services-company-do/ […]

… [Trackback]

[…] Find More Information here on that Topic: news969.com/what-does-an-electronic-design-and-manufacturing-services-company-do/ […]